Formwork systems / shuttering

Ready to install and individually assembled

We support our customers’ projects with tailor-made formwork systems made of profiled elements, individually assembled for the respective structural conditions.

The foundation formwork combines cost-effectiveness and user-friendliness. The work space required can be minimal. The low weight of the formwork material also makes it easier to work without additional machinery. As with all Hydra recess and formwork bodies, this formwork can also remain in the foundation.

Applications / Requirements

Strip formwork

Formwork “light version”

Formwork “reinforced”

Expanded metal panels

Designs

Strip formwork

Depending on the structural conditions or requirements, we supply a formwork system made of profiled U-shells, which can be installed in a very short time and is a cost-effective alternative to the “conventional side formwork” made of sheet steel. The short assembly time means that the formwork systems can be used quickly. This is also made easier by the fact that no special tools are required.

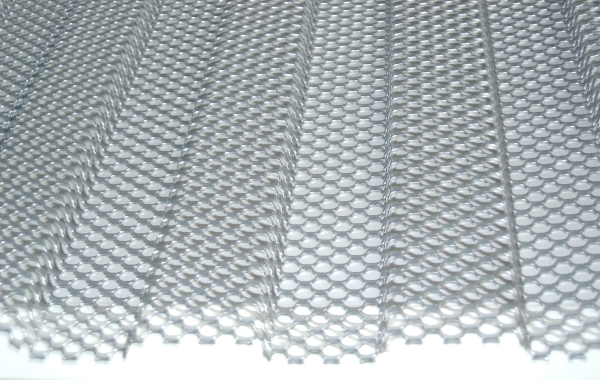

Formwork light design

In addition to the technical properties of a good bond between two concrete sections, the “light version” is characterized above all by a good price-performance ratio. This variant is used, among other things, in ceiling areas, at heights of 120 mm to 300 mm.

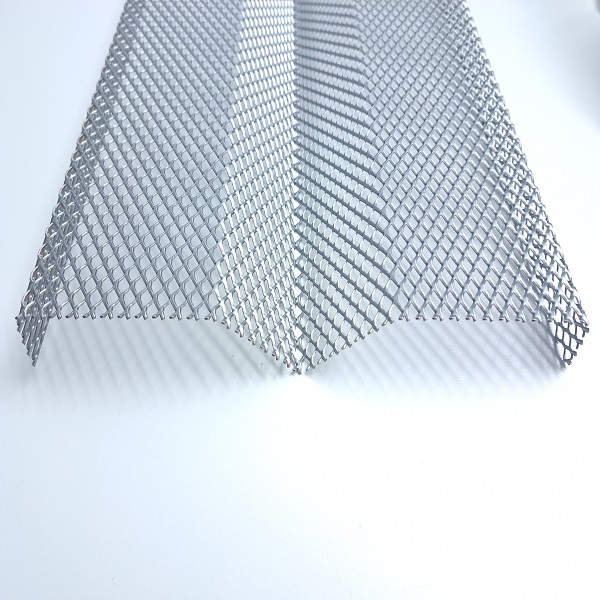

Formwork reinforced

The formwork elements made of profiled perforated sheet metal enable very good bonding and compaction in the joint area. The assembly on site is very simple by tying it to the reinforcement. The upstand height and width are based on your individual specifications. A high level of stability is achieved through appropriate material thickness and reinforcement brackets.

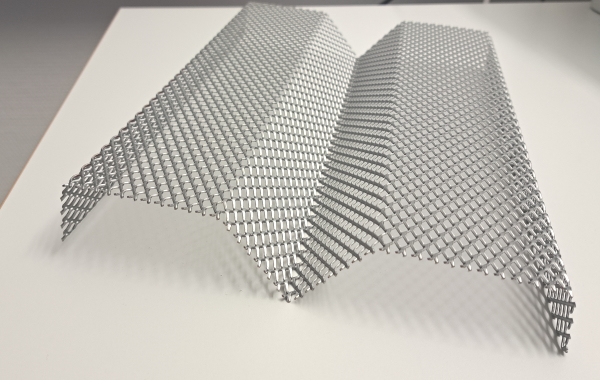

Expanded metal panels

Formwork is necessary for cost-effectiveness and rapid construction progress. It is used for installation between reinforcement levels and as stoppers in ceilings and formwork. In contrast to conventional formwork, the elements made from profiled “perforated sheet” can remain in the concrete, thus saving on formwork removal work and contributing to a high level of rationalization of the construction site.

Ordering instructions

Material

Perforated material “rolled” s = 1.00 mm

Length – preferably up to 2.00 m

Width/height – from 0.10 m to 0.30 m

Galvanized steelAll images shown are available in profiled perforated sheet metal as well as in “smooth” perforated sheet metal. Standard length in smooth version (preferably up to 2.00 m), height (h) according to your specifications.

Material

Profiled perforated sheet s = 0.50 mm

Length – according to your specifications

Width/height – from 0.30 m to 1.00 m

Reinforcing bracket – thickness 6 to 12 mm, depending on the construction height

left: formwork in floor slabs, different designs

Delivery with mounted reinforcement brackets

Material

Profiled perforated sheet s = 0.5 / 0.75 mm

Length – preferably up to 2.40 m

Width/height – from 0.15 m to 1.00 m

Depending on the application, the formwork can be supplied with

mounted U-brackets for fastening or

reinforcement. The formwork is supported on site, according to the respective conditions.

How can we help you?

Do you have any questions? We are happy to help you by phone or email!

wbr Rohr- und Bauelemente GmbH

Otto-Hahn-Straße 17

D 75248 Ölbronn-Dürrn